Cold Plates

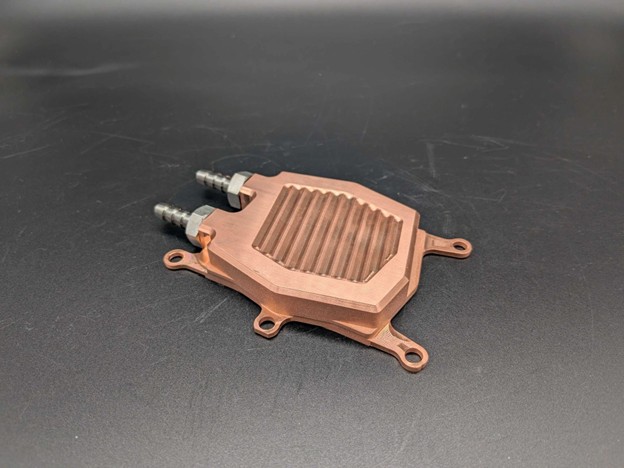

Alloy’s aluminum cold plates provide superior thermal conductivity and enhance cooling performance for thermal management applications.

Heat transfer is critical to the performance of our products; 40% improvements become game-changers.

~Rob Martinsen, CTO/nLIGHT

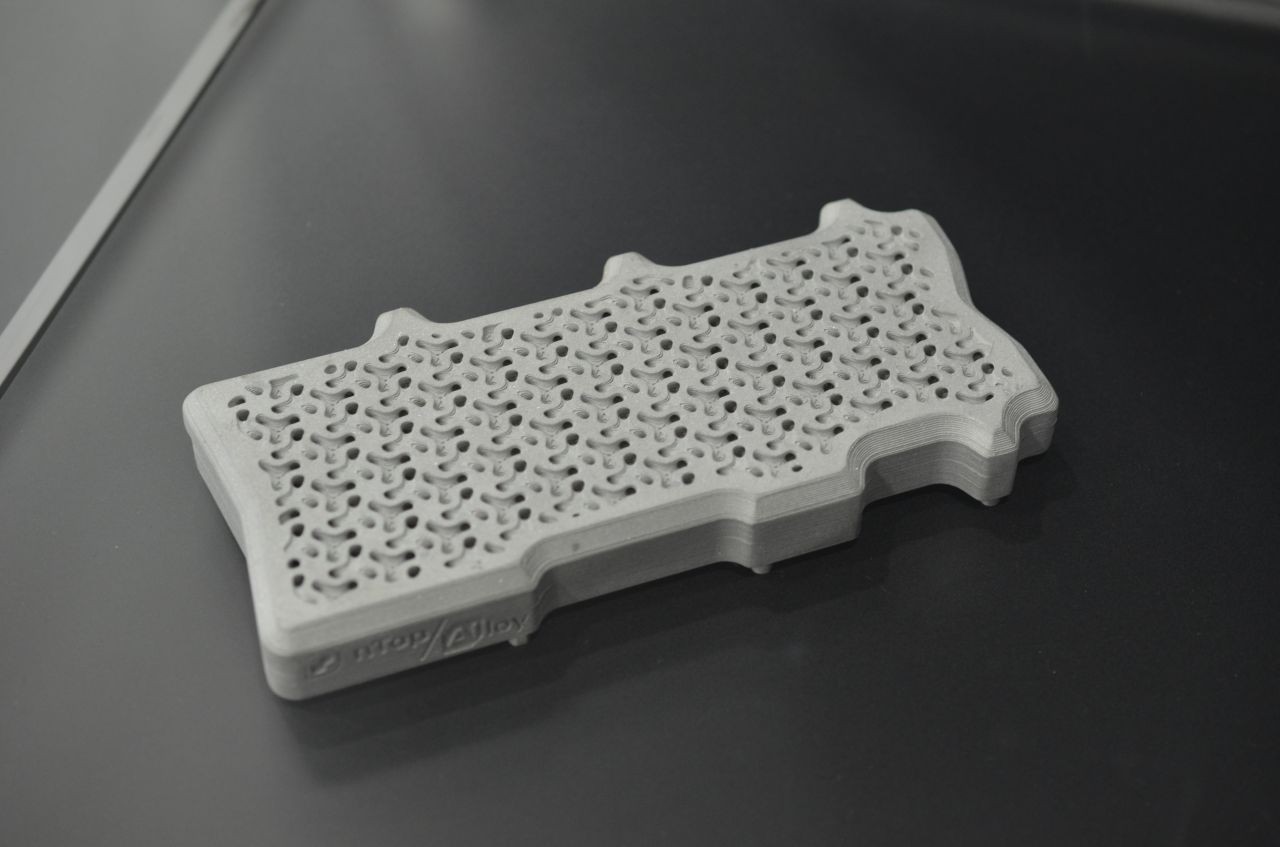

Cold plates with a new level of performance

New, hotter chips demand a new, higher performance thermal solution. Using their patented Stack Forging™ method to create novel micro-geometries, Alloy produces cold plates that out-perform older technologies. In fact, Alloy’s proprietary cold plates can deliver up to 18% improvement in PUE (Power Usage Effectiveness), enabling higher levels of compute for data center operators.

Benefits of Alloy Enterprises

Reduced PUE

Lower PUE by up to 18% to get more compute output per KW

Lower Pressure Drop

Less wear and tear on pumps improves reliability

Single-piece Construction

Eliminate the risk of expensive field failures and simplify the design

Forem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos.

Company Name

~ Industry

News

Alloy Enterprises Unveils Copper Direct Liquid Cooling, Slashing AI Data Center Energy Use and Eliminating the Need for HVAC

How Can We Help?

Share your cold plate manufacturing challenges. Our team is here to assist today.