Peripherals Are the New Thermal Limit, Here’s How to Cool Them.

See how single-piece cold plates deliver reliable cooling for every component in our new eBook.

Cooling At Any Scale.

High-performance, leak-tight thermal management components built to cool where it matters most.

A New Generation of Thermal Management

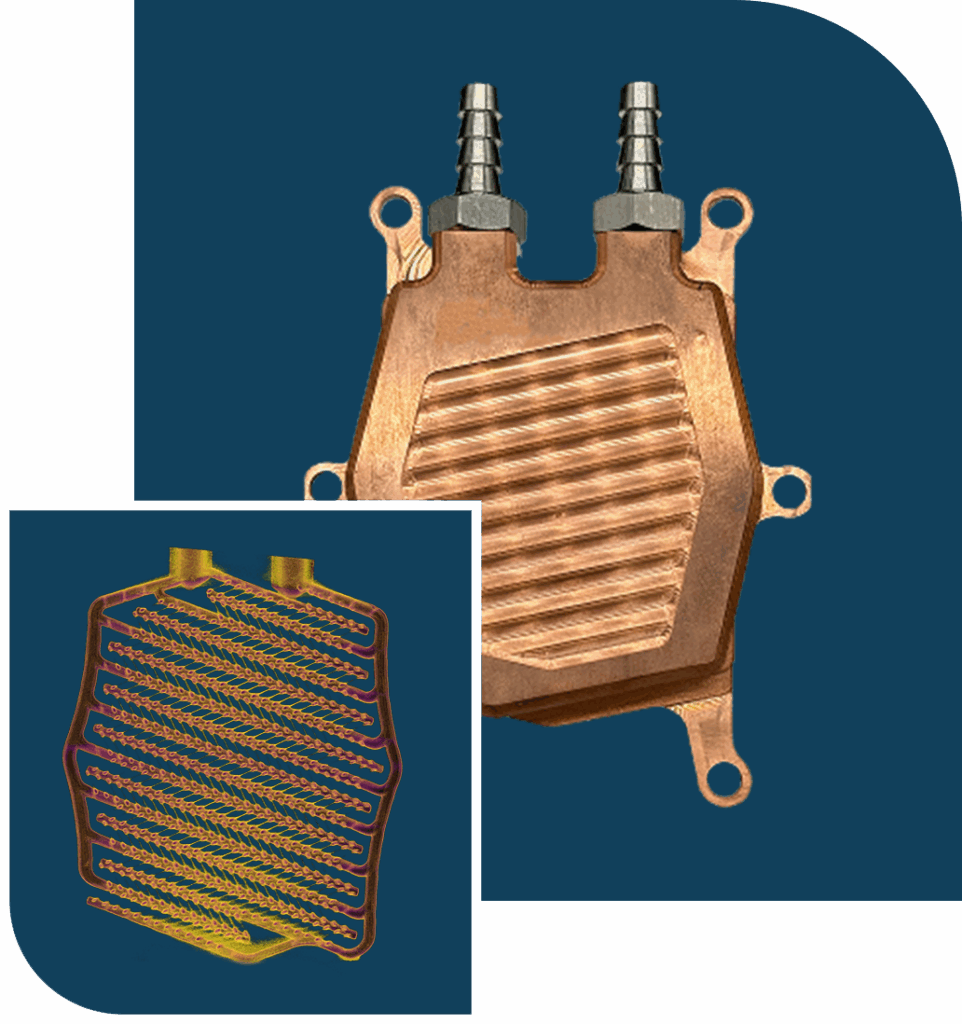

From processors to peripherals, and across defense electronics and industrial systems, Alloy delivers leak-tight, single-piece thermal management components engineered for maximum heat transfer and low pressure drop, built to perform under the most crushing thermal loads and solve the industry’s toughest thermal challenges.

Ideal for:

- Direct liquid cooling (DLC) components

- High-efficiency vapor chambers

- Oscillating heat pipes

- Wafer cooling chucks

- Electronics enclosures with integrated cooling

Custom Needs?

We specialize in tailored thermal solutions that can be rapidly iterated using our Digital Manufacturing Suite + Stack Forging™, enabling rapid, tooling-free design cycles.

What Sets Us Apart

Custom Manufacturing for the Brands you Trust

Unlocking Next-Generation Thermal Applications

Alloy components provide exceptional heat transfer, lower pressure drop, and leak-tight, single-piece construction for:

Microgeometries You Can’t Get Anywhere Else

Our proprietary library of plug-and-play microgeometries, impossible to manufacture with any other process, deliver:

Targeted Cooling

Focused heat extraction where it matters most

Complex Microchannels

Boost thermal performance

Parallelized Flow Paths

Reduce pressure drop

Fully Dense, Leak-Tight Material

Suitable for ultra-high vacuum

Engineered to Cool. Built to Scale.

Measuring Excellence

Parts

Manufactured

Pounds of

Aluminum Used

Projects

Completed

End-to-End Support

Our engineers partner with you at every stage: design, simulation, testing, and production.

Design

Tailored solutions to meet your specs

Simulate

Multi-physics CFD and thermal-structural FEA

Test

In-house thermal, mechanical, and leak testing