Why Alloy Enterprises?

Alloy offers components with new levels of thermal performance, produced domestically to ensure your supply chain is never at risk.

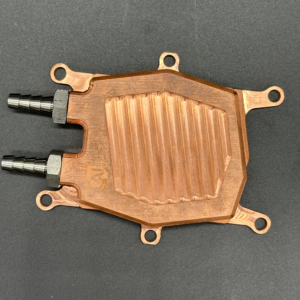

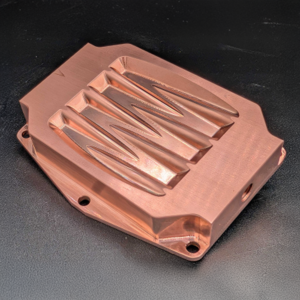

A Dramatic Improvement in Liquid Cooling

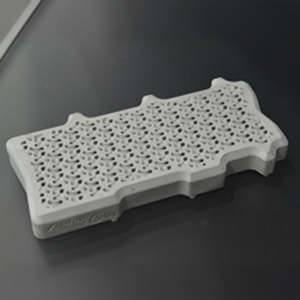

Alloy’s patented Stack Forging™ manufacturing process enables new designs that simply cannot be manufactured with other methods. Alloy produces complex end-use components with the material properties of wrought aluminum and copper but with novel geometries only possible through our Stack Forging manufacturing process.

Compare Alloy to Traditional Manufacturing

With Alloy Enterprises, you get the best of both worlds — the flexibility of superior material properties with the geometric complexity to build lightweight aluminum and copper components. Our full-stack process is scalable and helps customers accelerate time to market with rapid delivery.

| Perfect for... | 3D Printing | Machining | Casting | |

|---|---|---|---|---|

| Material Properties | ||||

| Fully Dense (no porosity) | ||||

| Complex Geometries | ||||

| High Volume Production | ||||

| Rapid Design Iteration | ||||

| Short Lead Time | ||||

| Cost |

The Alloy Advantage

High Thermal Performance

Alloy’s patented fabrication process enables proprietary 3D micro-structure designs

High Reliability

Made for Lightweight

Design Services

Superior Material

Properties

Alloy’s components are made from 6061-T6 aluminum with material properties that surpass cast or machined parts, and copper 110 components meet ASHRAE standards for chemical compatibility.

US-Based Production

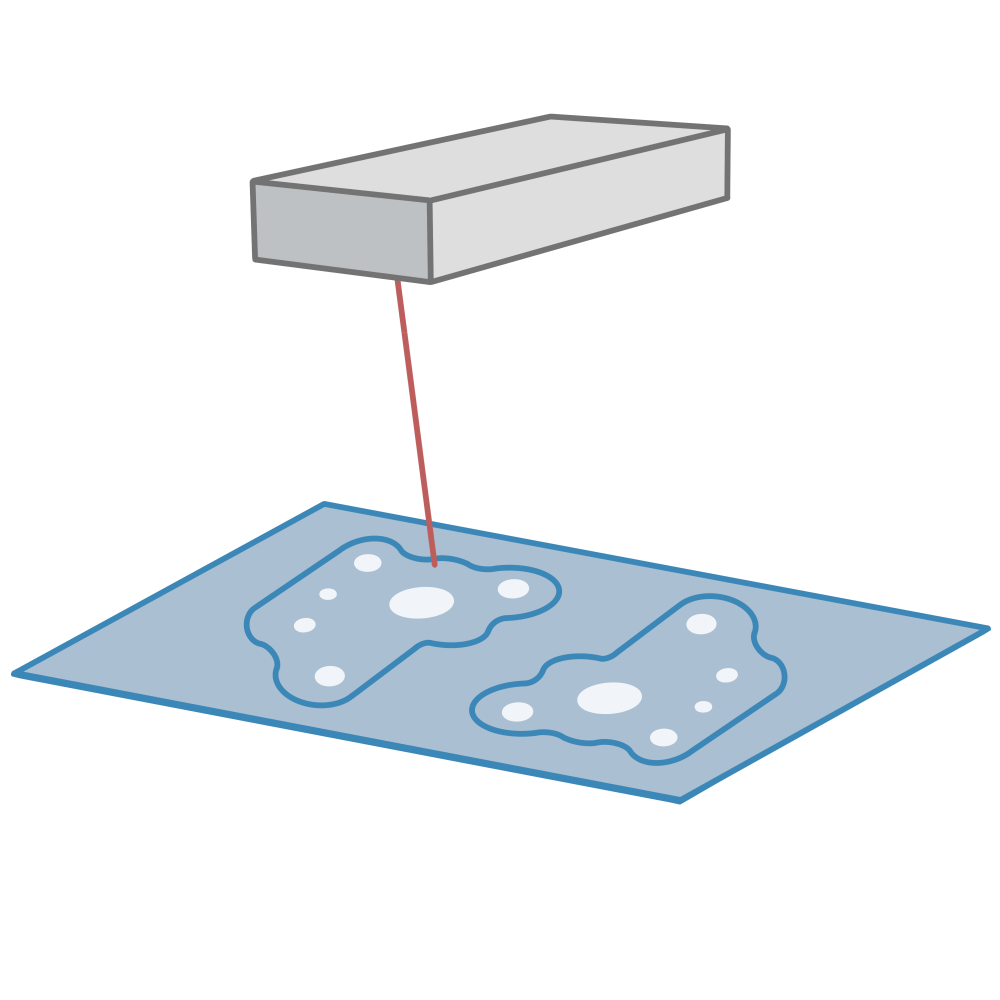

The Stack Forging™ Process

Layer Creation

The first step in the Alloy manufacturing process starts with digitally slicing the 3D model into discrete layers. Slicing is followed by laser-cutting the design into sheets from our custom feedstock.

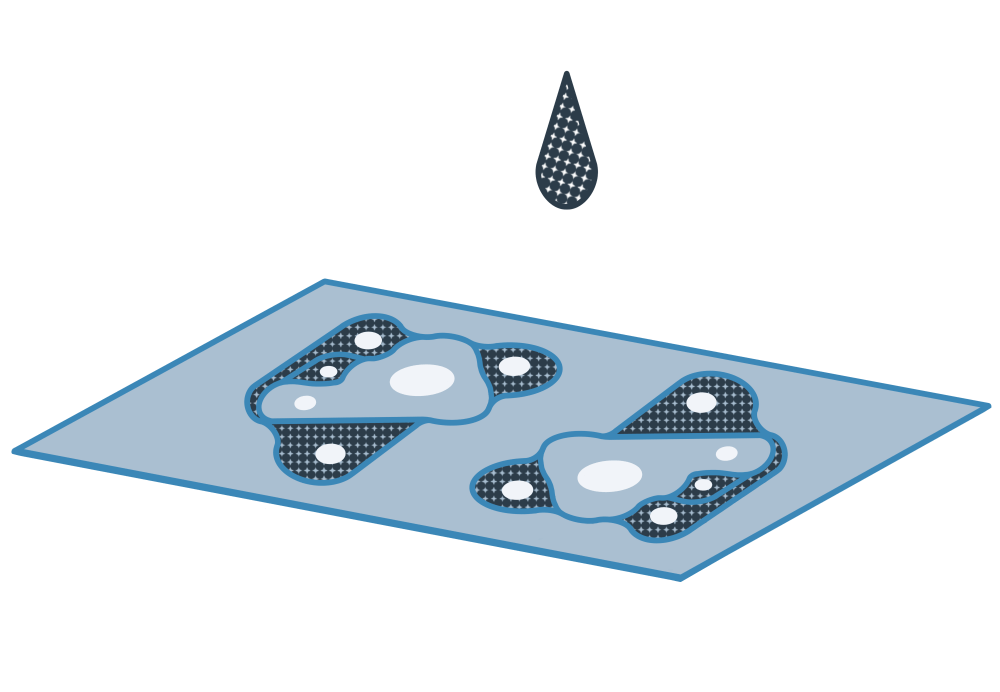

Inhibition

Next, an agent is selectively applied to create an inhibition layer in designated areas of the design and act as a mold release.

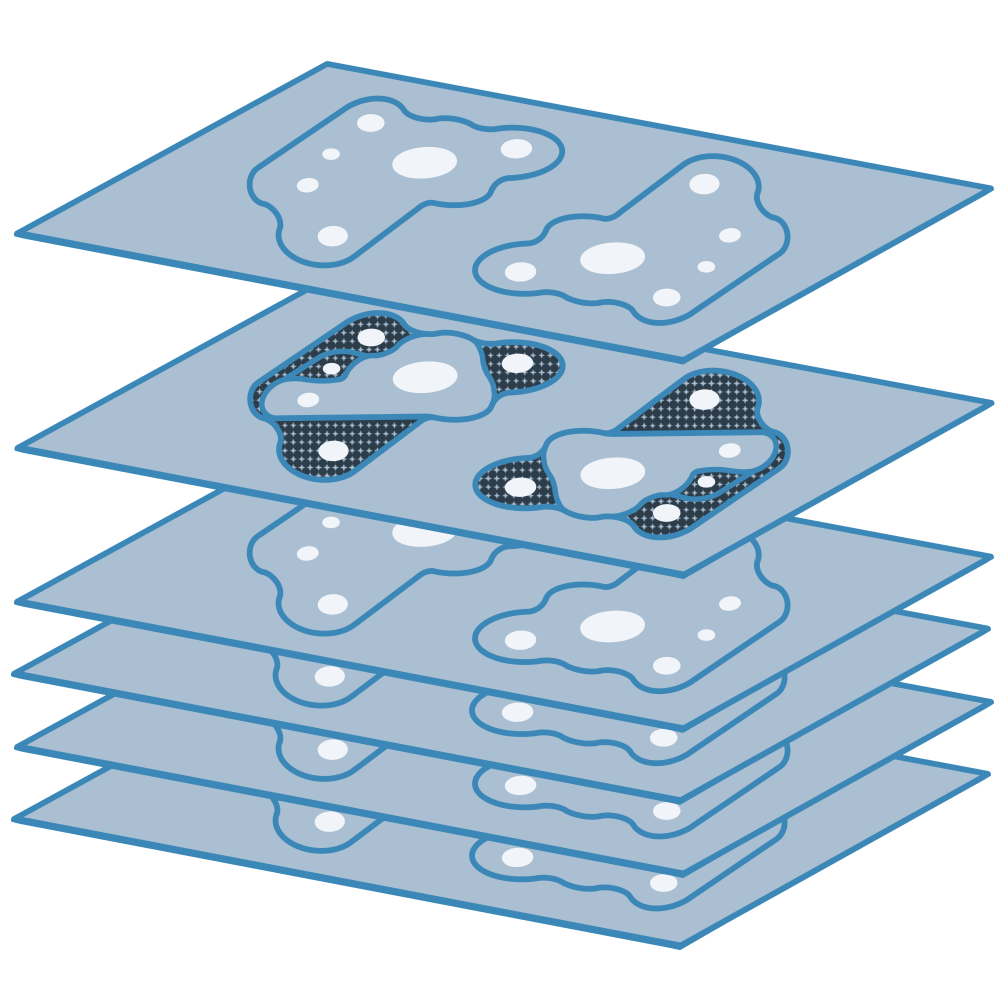

Stacking

To ensure tight tolerances, the sheets are stacked and registered.

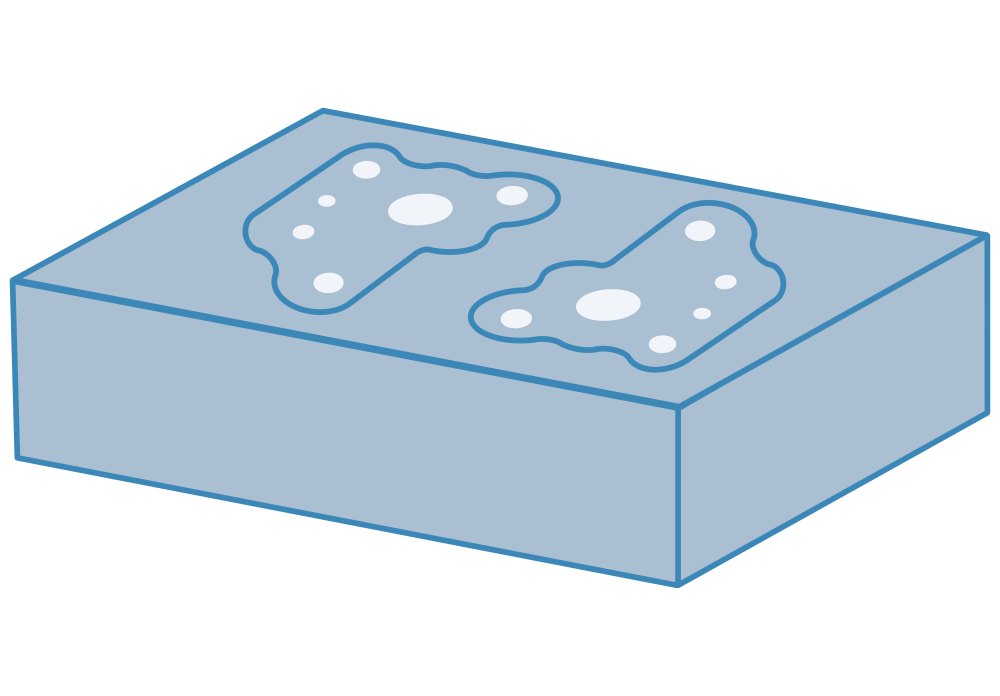

Bonding

The sheets are then metal to metal diffusion-bonded together to form a solid block.

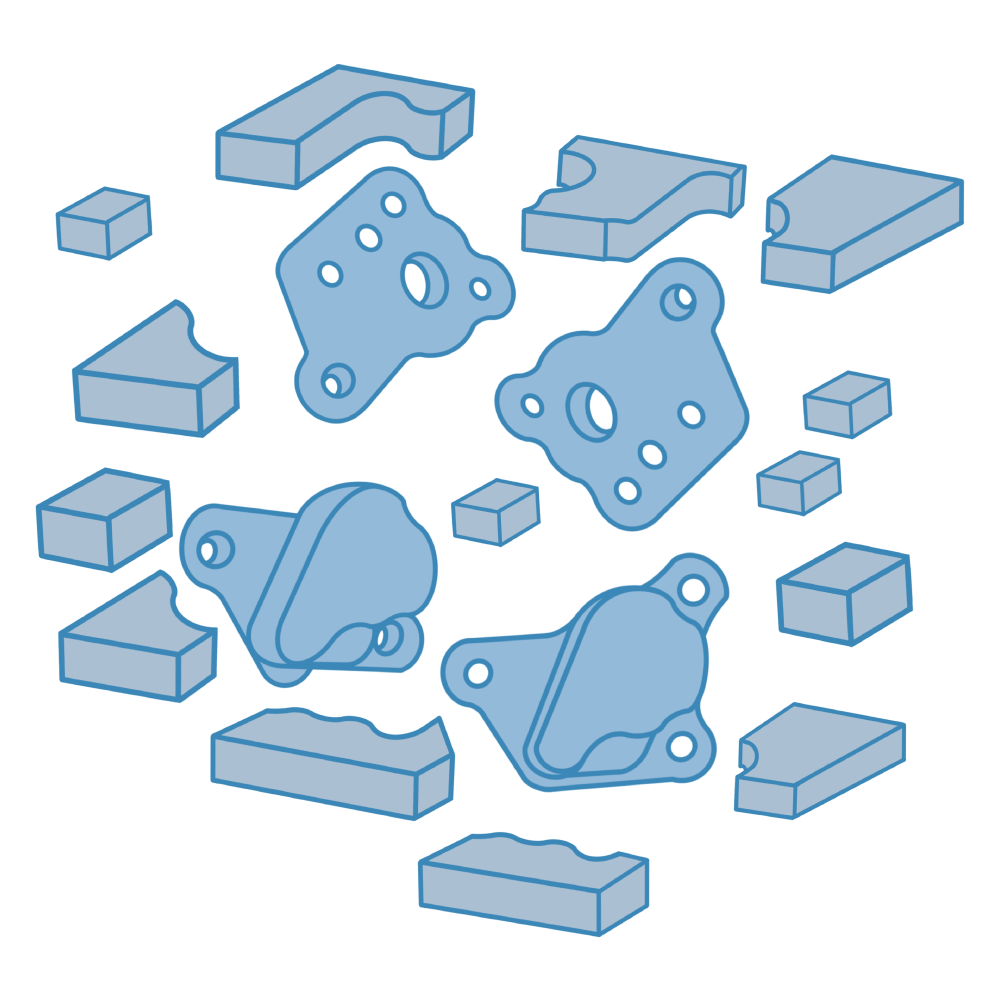

Heat Treatment

Once the block is formed, the support material is removed and the components are heat-treated for strength and hardness.

Forem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos.

Company Name

~ Industry

How Can We Help?

Our applications engineers and manufacturing experts partner with you through every stage from design and simulation to manufacturing, testing and qualification. Whether you’re building a new thermal solution or optimizing an existing one, Alloy delivers end-to-end support from design to part production

Design

Alloy’s applications engineers work with your team to produce a design that meets your needs.

Simulate

Alloy uses a variety of simulation tools including multi-physics thermal-fluid CFD and thermal-structural FEA methods.

Test

Alloy performs a wide variety of tests in-house, including thermal, mechanical and leak testing.