Defense Electronics

Enhance mission-critical defense electronics with Alloy’s advanced thermal management solutions. Our proprietary Stack Forging™ technology delivers unmatched heat transfer, structural integrity, and weight savings.

High Performance Thermal Solutions for Defense Electronics

As defense electronics grow more powerful, they concentrate heat into tighter spaces, exceeding the limits of conventional cooling methods. These compact, high-power systems require thermal management solutions that are not only efficient, but also lightweight and durable enough for extreme environments.

Alloy’s Stack Forging™ manufacturing process meets that challenge.

Alloy delivers thermal management solutions with low thermal resistance and minimal pressure drop, while providing the strength and design flexibility required for demanding defense environments.

Alloy’s Unique Capabilities

Applications include:

- Embedded defense electronics

- Missiles & radar systems

- Directed energy & high-power lasers

- Cooled mirrors

- Oscillating heat pipes

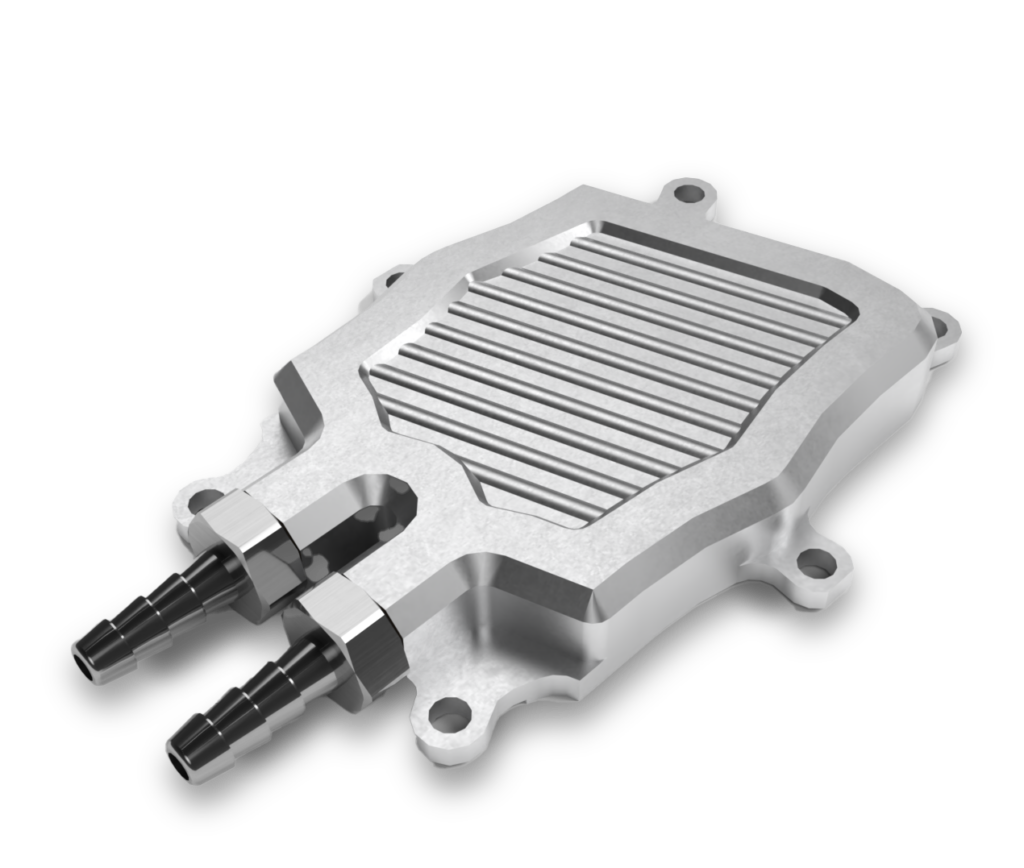

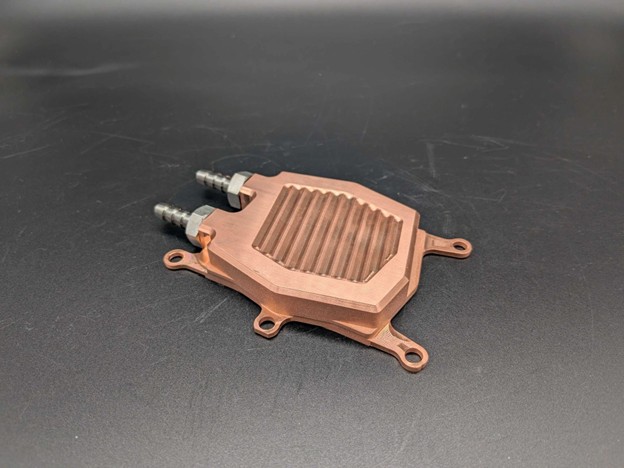

- Cold plates

Don’t see your exact use case? We specialize in tailored thermal solutions, let’s talk.

Benefits

Improved Thermal Control

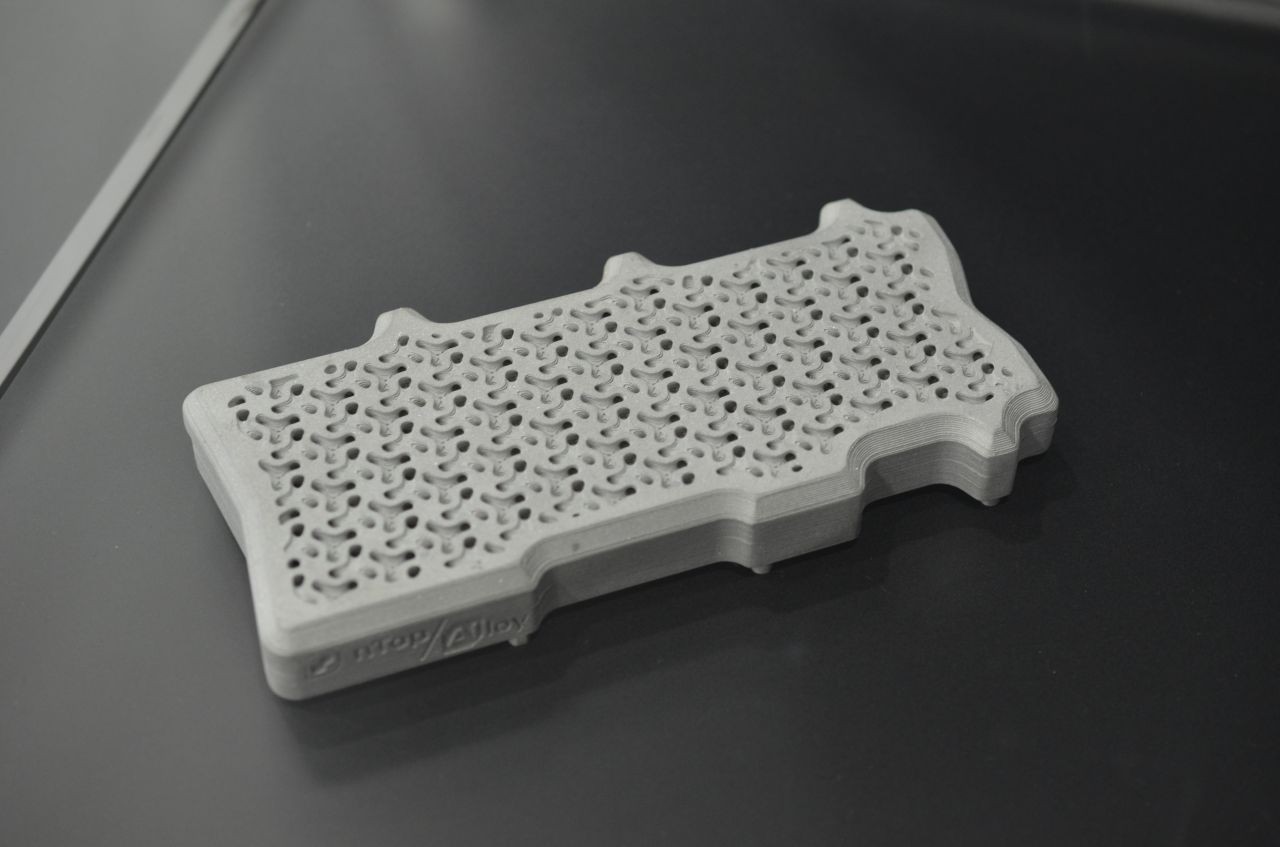

Precision microchannels ensure efficient heat removal for reliable performance

Single-piece Construction

Monolithic design eliminates expensive field failures and simplifies design

Lower Weight

Lightweight aluminum parts boost mobility and reduce energy use

Forem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos.

Company Name

~ Industry

News

Alloy Enterprises Unveils Copper Direct Liquid Cooling, Slashing AI Data Center Energy Use and Eliminating the Need for HVAC

How Can We Help?

Our applications engineers and manufacturing experts partner with you through every stage from design and simulation to manufacturing, testing and qualification. Whether you’re building a new thermal solution or optimizing an existing one, Alloy delivers end-to-end support from design to part production.

Design

Alloy’s applications engineers work with your team to produce a design that meets your needs.

Simulate

Alloy uses a variety of simulation tools including multi-physics thermal-fluid CFD and thermal-structural FEA methods.

Test

Alloy performs a wide variety of tests in-house, including thermal, mechanical and leak testing.