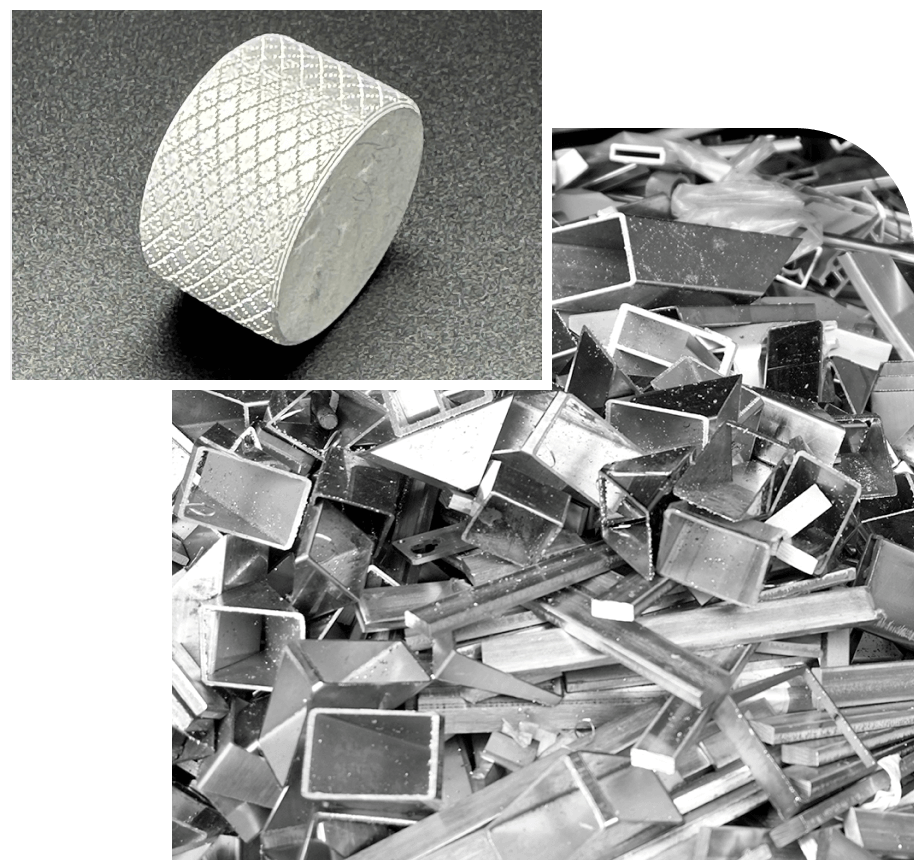

Alloy's material is infinitely recyclable

Our local production using custom feedstock with superior material properties promotes green manufacturing. Alloy is the preferred custom aluminum parts supplier and our innovative Stack Forging™ process is the alternative to traditional casting or 3D printing methods.

Increasing Production While Reducing Environmental Impact

With the backing of several investors, we’ve developed a new way to make aluminum parts. This breakthrough delivers sustainability benefits to the e-mobility, heavy equipment, and industrial product industries; ideal for thermal management and aftermarket applications.

Time

Properties

Accuracy

Key Benefits of Alloy's Unique Process

Sustainable, Reusable, Scalable

Aluminum’s Material Properties

Aluminum is 100% recyclable and its excellent strength-to-weight ratio ensures structural integrity, yet weighs up to 65% less than steel. Recycling aluminum reduces energy-related greenhouse gas emissions by up to 95%.

Aluminum’s Material Properties

Measuring Excellence

Parts

Manufactured

Pounds of

Aluminum Used

Projects

Completed