Industrial

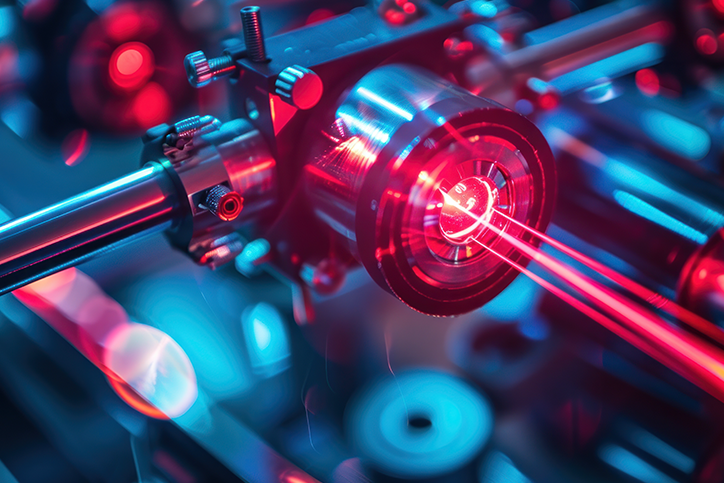

Lasers and industrial electronics are getting smaller and hotter, making thermal management increasingly challenging. Alloy’s proprietary components deliver next-gen cooling enabling high performance stability for industrial lasers, semiconductor test equipment, & cooling of industrial electronics.

Cooler Parts and Increased Throughput

Alloy’s proprietary design and manufacturing process enables precise heat extraction from lasers and optical devices, reducing weight, improving wavelength stability, and enhancing optical precision—driving higher throughput and performance across industrial applications.

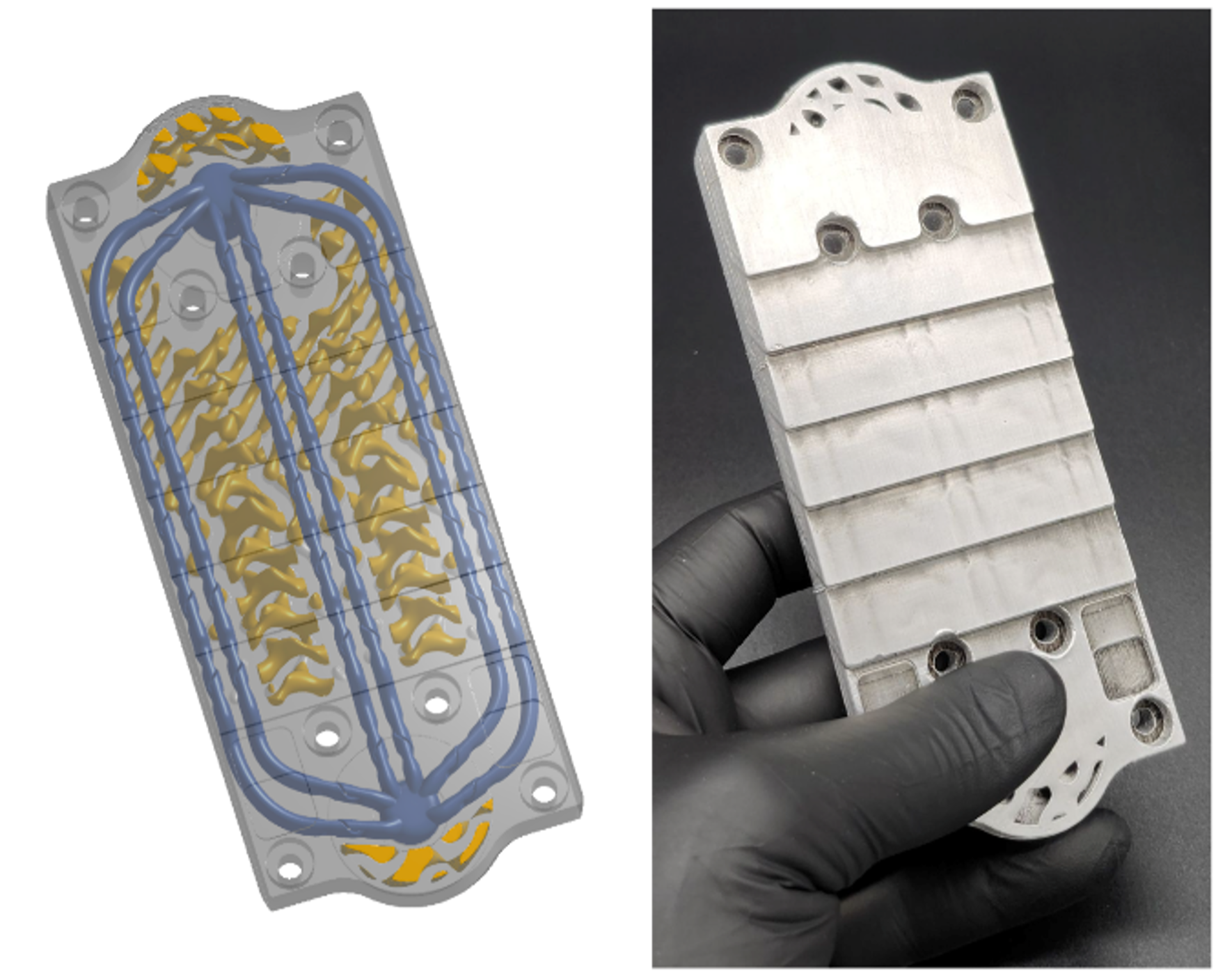

Stacked Forged Solutions for Peak Performance

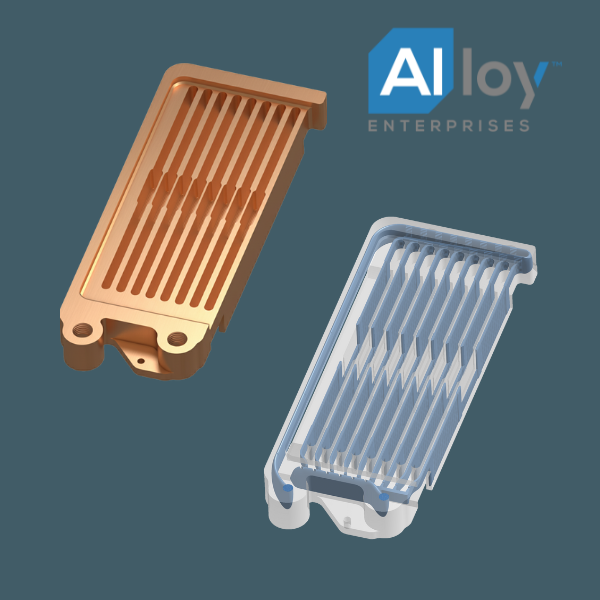

Increase power density, thermal stability, and reliability with Alloy’s aluminum and copper cooling components. Our configurable microchannel architecture delivers targeted cooling exactly where high-power diode laser systems need it—ensuring stable output and consistent thermal control in compact designs.

Applications include:

- Semiconductor test equipment

- Industrial laser systems

- Cooling of industrial electronics

Don’t see your exact use case? We specialize in tailored solutions, let’s talk.

Forem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos.

Company Name

~ Industry

Benefits

Precision Cooling

Targeted heat extraction ensures optimal performance of sensitive components

Compact Design

Monolithic structures reduce size and weight, ideal for space-constrained applications

Enhanced Reliability

Elimination of joints and seals minimizes failure points, ensuring long-term stability in rugged environments

News

Johnson Controls signs agreement to acquire Alloy Enterprises strengthening data center thermal management leadership

Alloy Enterprises Extends Direct Liquid Cooling Across the Blade, Eliminating the 100 kW Peripheral Heat Bottleneck

How Can We Help?

Our applications engineers and manufacturing experts partner with you through every stage from design and simulation to manufacturing, testing and qualification. Whether you’re building a new thermal solution or optimizing an existing one, Alloy delivers end-to-end support from design to part production.

Design

Alloy’s applications engineers work with your team to produce a design that meets your needs.

Simulate

Alloy uses a variety of simulation tools including multi-physics thermal-fluid CFD and thermal-structural FEA methods.

Test

Alloy performs a wide variety of tests in-house, including thermal, mechanical and leak testing.