Data Center Cooling

Alloy’s Direct Liquid Cooling Solutions

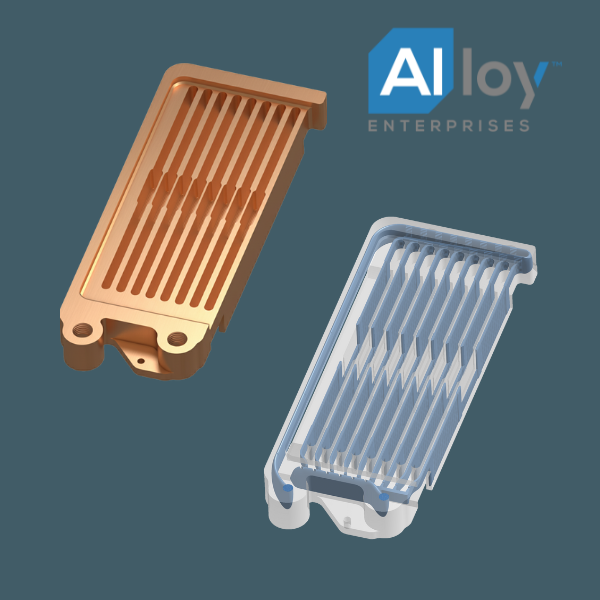

Our DLC components feature proprietary microgeometries with high precision microchannels throughout the components enabling peak 3D flow performance delivering:

- High heat transfer

- Lower pressure drop

- High pressure capability

- Leak-tight design (no brazing or solder joints)

- Up to 4,350W cooling capacity

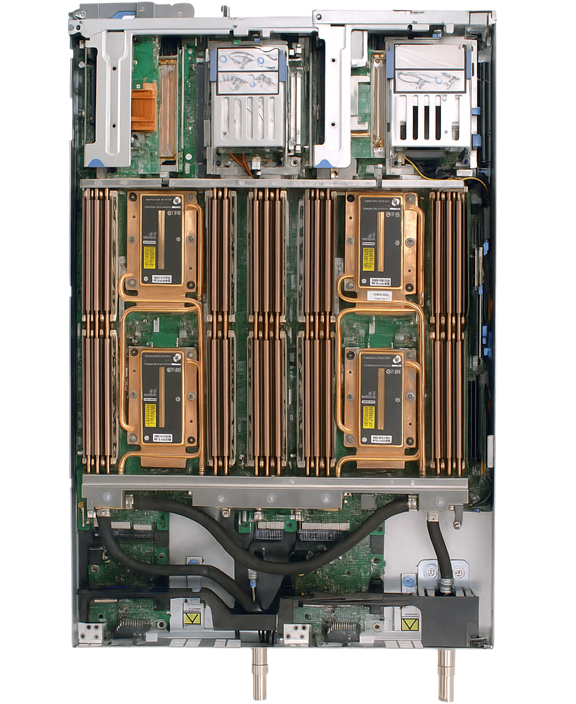

Our solutions support 100% full-blade DLC, covering CPUs, GPUs, DIMMs, NICs, QSFPs, and other peripherals, enabling scalable, end-to-end thermal management across dense server blades and racks.

Comprehensive Cooling for Server Peripherals

As servers get denser, peripherals like DIMMs, NICs, and QSFPs are turning into thermal bottlenecks. Alloy’s DLC solutions deliver consistent cooling across every blade, keeping systems reliable under higher loads.

Key Features for DIMMs and Peripherals

- Single-Piece Cold Plate – No solder or brazing

- Double-Sided DIMM Cooling – Efficiently cools every stick

- Serviceable Design – Remove or upgrade DIMMs in the field

- Next-Gen Ready – Built to meet JEDEC specs for 25 W per DIMM

- Auxiliary Component Cooling – Eliminates hotspots

With integrated peripheral cooling, Alloy enables efficient heat removal at scale, unlocking higher TDPs, greater reliability, and maximum compute density.

Industry-Leading Energy Savings and Thermal Performance with Copper and Aluminum DLC

Our DLC components reduce thermal resistance by 35% and pressure drop by 4× compared to leading industry designs. This enables higher TDP chips, improves PUE by up to 18%, driving greater compute density and energy efficiency for hyperscalers, colocation providers, and data centers.

Learn more about our capabilities in our latest whitepaper!

Try It for Yourself

Got a thermal challenge? Let’s solve it together. Alloy’s monolithic, microcapillary cold plate technology delivers industry‑leading heat transfer, lower pressure drop, and scalable cooling for high‑power servers.

Whether you’re tackling a thermal bottleneck, evaluating a new design, or exploring full‑blade liquid cooling, Alloy can help you engineer a solution that meets your needs.

Reach out and start the conversation.

Benefits

Maximize Compute Revenue

Lower PUE by up to 18%. More performance per kilowatt

Zero Leak Points

Monolithic design eliminates failure risk and simplifies systems.

Slash Energy Use

5x lower pressure drop cuts pump power.

Forem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos.

Company Name

~ Industry

News

Johnson Controls signs agreement to acquire Alloy Enterprises strengthening data center thermal management leadership

Alloy Enterprises Extends Direct Liquid Cooling Across the Blade, Eliminating the 100 kW Peripheral Heat Bottleneck

How Can We Help?

Alloy’s solutions provide lightweighting, integrated cooling, power efficiency, and system optimization to help prevent overheating while ensuring optimal performance for protecting resources such as high density servers, critical IT equipment, and machinery. From design and simulation to manufacturing, testing and qualification, Alloy delivers end-to-end support.

Design

Alloy’s applications engineers work with your team to produce a design that meets your needs.

Simulate

Alloy uses a variety of simulation tools including multi-physics thermal-fluid CFD and thermal-structural FEA methods.

Test

Alloy performs a wide variety of tests in-house, including thermal, mechanical and leak testing.